In 2023, Sinotruk's Yellow River X7 set a Guinness World Record for 'longest distance traveled by a semi-trailer truck on a single fuel fill' with 4,871.18 kilometers.

At the 2024 IAA Transportation in Hannover, Germany, Sinotruk showcased its newly upgraded Yellow River hydrogen internal combustion engine tractor train. The innovative streamlined design combined with hydrogen internal combustion engine achieves perfect integration of ultra-low wind resistance and zero carbon emissions. With a drag coefficient reduced to 0.286, it again breaks the low-resistance limit for commercial heavy trucks, improving vehicle energy efficiency by 15%. This fully demonstrates Sinotruk's cutting-edge technological capabilities, driving the global commercial vehicle industry toward a greener, smarter, and more efficient future.

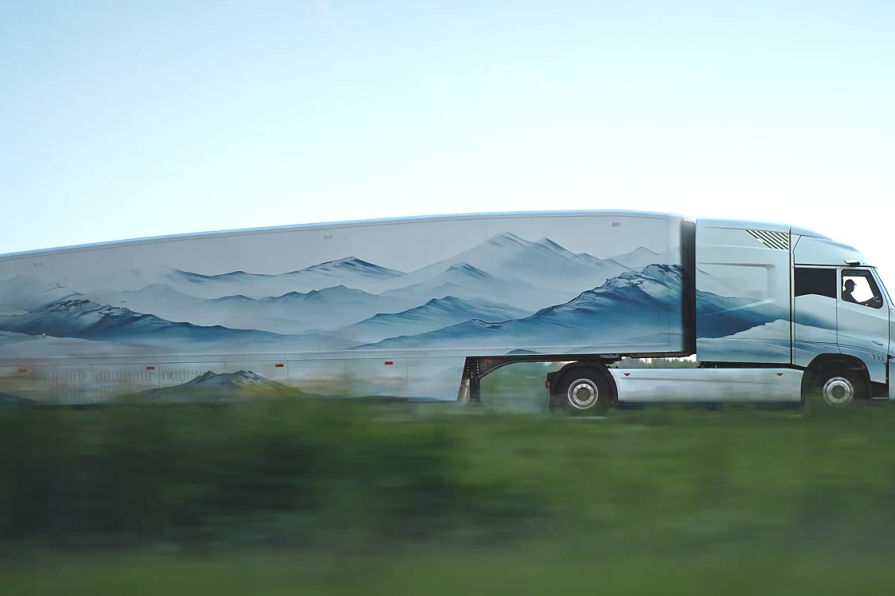

Today, let's take a closer look at Sinotruk's masterpiece - the Yellow River hydrogen internal combustion engine tractor!

Design Inspiration

The Yellow River hydrogen internal combustion ultra-low resistance tractor train adopts bionic design, with overall vehicle styling drawing inspiration from natural forms like water droplets and fish. It integrates the cab and trailer design, combining a 'raindrop' body shape with 'bionic fish back' trailer styling. The entire train features streamlined contours, presenting optimal aerodynamic shape and characteristics.

For resistance reduction details, hidden door handles and electronic rearview mirrors were designed to minimize the vehicle's frontal projection area. During high-speed operation, airflow passes smoothly around the vehicle body, compressing the low-pressure zone at the rear, minimizing both viscous resistance and positive pressure, ultimately achieving an ultra-low drag coefficient of 0.286 for the entire train.

Ultra-low Drag Coefficient

The Yellow River hydrogen internal combustion tractor train's drag coefficient is 0.286, while medium and large SUVs typically have drag coefficients around 0.3. Achieving a better drag coefficient than an SUV for a heavy-duty truck puts it far ahead in the heavy truck industry.

Sinotruk began investing in low-resistance heavy truck product research and design in 2012, building an aerodynamic simulation and R&D design team of over 120 people. After more than a thousand days, the team completed the development of the ultra-low resistance train, obtaining over 30 invention patents. During this process, the team conducted over 500 rounds of high-precision CFD simulation optimization, went through 3 prototype iterations and 10 wind tunnel tests. They became the first in the industry to equip heavy trucks with active intake grilles, electronic rearview mirrors, hidden door handles, and over 20 airflow control accessories, achieving Sinotruk products' ultimate transformation, gaining authoritative certification from domestic and international organizations including CATARC, TÜV Rheinland, and IDIADA.

Longest Driving Distance

Leveraging Shandong Heavy Industry Group's resource advantages and integrating multiple fuel-saving technologies such as high thermal efficiency powertrain and low-resistance train design, the Yellow River series created a Guinness World Record in 2022 by traveling 4,871.18 kilometers on a single fuel fill under full load.

In the application of more environmentally friendly hydrogen fuel technology, Sinotruk has invested heavily in research and development, achieving excellent results. The company was the first in the industry to successfully develop and commercialize a 15L large-displacement, high-power hydrogen internal combustion engine, achieving an industry-leading thermal efficiency of 45.03%. Furthermore, equipped with a 2800L/70MPa high-pressure, high-capacity hydrogen storage system, combined with the train's ultra-low fuel consumption, it achieves a range of 1,100km, fully meeting long-distance logistics transportation needs without range anxiety.

Additionally, Sinotruk developed a fully autonomous PCU intelligent vehicle control system that enables intelligent torque control, intelligent brake management, intelligent thermal management, and full-scenario energy management functions, allows vehicles to operate in the most fuel-efficient and high-performance state, achieving both fuel economy and performance optimization.

The introduction of the Yellow River ultra-low resistance heavy truck provides new ideas for commercial vehicle energy conservation and carbon reduction, bringing new vitality to the transportation industry and higher economic benefits for users.

Cab Design

Beyond its futuristic appearance and power system, the Yellow River hydrogen internal combustion tractor train's cabin features dual high-definition large screens for the intelligent cockpit. It also integrates precise voice capture interaction system, convenient mobile App control functions, and intelligent driving assistance features such as 360-degree panoramic view and blind spot warning, further enhancing safety.

The cabin adopts a front-door design, fully considering driver experience and optimizing entry and exit convenience. Features like a starry roof, NVH optimization, and clean top design provide drivers with a quieter and more spacious driving environment. Additionally, the vehicle is equipped with an onboard refrigerator, power inverter, multifunctional table, and fold-down lower berth, offering comfortable rest facilities and providing more thoughtful and convenient living services for long-distance drivers.

As a backbone of China's commercial vehicle industry, Sinotruk possesses deep technical accumulation and rich production experience. With nearly 1,000 dealership networks and 80 overseas offices established globally, it has formed a worldwide marketing and service network, perfectly combining Chinese aesthetic essence with green technology, showcasing the tremendous appeal of Chinese manufacturing, and marking its role as a leader in the global commercial vehicle new energy development.

鲁公网安备37010202000616号

鲁公网安备37010202000616号